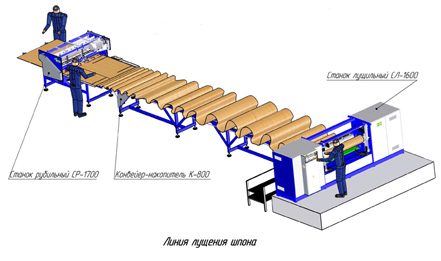

ÑË-1700Machine for the production of peeled veneer

Machine is designed for production of peeled veneer from deciduous and coniferous veneer logs and simultaneous splitting of veneer ribbon into stripes of necessary width.

The machine is equipped with a conveyor that discharge the waste for disposal from the cutting zone bark and veneer unusuitable for further use.

In order to increase productivity and convenience of operator's work the machine is equipped with hydraulic lifting-and-centering device allowing to determine automatically the most optimal billet rotation axis and its alignment with centering shafts rotation axis.

Veneer required thickness between 0.8 - 3.6 mm is set on the machine control panel and maintained during the entire peeling cycle with electronic system.

| Technical characteristics |

| |

| Diameter of workpiece |

| |

210-600 |

ìì |

| Length of workpiece |

| |

1600-1750 |

ìì |

|

Video

|

| Thickness of veneer |

| |

0,8-3.6 |

mm |

| Productivity |

| |

3,2…16 |

m3 /shift |

| Fixed power capacity |

| |

24,5 |

kW |

|

| Overall dimensions |

| Length |

4400 |

mm |

| Width |

1105 |

mm |

| Height |

1365 |

mm |

| Weight |

| |

4400 |

kg |

|

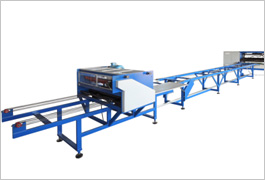

ÑÄ-1700Recut - machine for veneer cutting

Designed for dividing strip veneer workpiece on widths from 550 to 2200 mm.

The required width of the workpiece is set by the operator at the control panel.

Rotary cutting method allows splitting of moving veneer quickly (speed to 0.82 m / s ) and precisely.

| Technical characteristics |

| |

| Size of veneer |

| the width, no more than |

1750 |

mm |

| the depth |

0,75…3,65 |

mm |

| Number of blades |

| |

1 (2) |

piece |

|

|

| Width of the received planks/sheets |

| |

1100…2200

(550…1100) |

mm |

| Feed rate of veneer |

| |

0,825 |

meters per minute |

| Productivity |

| |

90….2250 |

pieces/min |

| Fixed power capacity |

| |

6,25 |

kW |

|

| Overall dimensions |

| Length |

3625 |

mm |

| Width |

2160 |

mm |

| Height |

1750 |

mm |

| Weight |

| |

970 |

kg |

|

Ê-800The storage conveyor

The conveyor K-800 is installed between the peeling and recut machine and is designed to accumulate veneer before the recut machine.

| Technical characteristics |

| |

| Maximum load capacity |

| |

300 |

kg |

| Distance between the axes of chains |

| |

800 |

mm |

| Height Floor-to-chain |

| |

1020…1060 |

mm |

|

|

| Electrical characteristics |

type of current

supply chain |

Variable,

three-phased |

|

| the frequency |

50 |

Hz |

| voltage |

380 |

V |

| engine power * |

1,5 |

kW |

| Pneumosystem characteristics |

| estimated operating-system air pressure |

0,6 (6,0) |

MPa

(kgf/cm2) |

| the degree of purification of compressed air |

Not ruder than 10 grade by GOST17433-80 |

|

|

| Overall dimensions |

| Length |

9150 |

mm |

| Width |

900 |

mm |

Height

(with raised forks) |

1750 |

mm |

| Weight |

| |

500 |

kg |

|

* Set in agreement with the consumer of a particular machine.

Production line of peeled veneer 1700 mm is recommended to set with the machine for debarking logs before peeling ÑÖ -2,2.